Product Highlights

Aluminium

Standard Socket- Get Details

Electroforge Gratings

- Electroforged Grating

- Advantages

- Galvanizing Process

- Stair Tread

- Technical Data

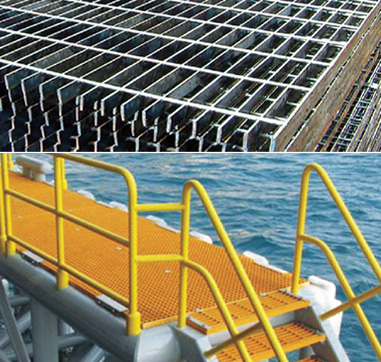

- Applications

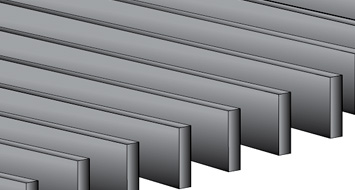

Electroforged Grating is PLC woven grid, pressed and welded in between load bearing bars with twisted cross bars that provides anti-skid floor surface, which allows air, light, heat, water etc. Electroforged machines cover comprehensive range of bearing bars(2-0.3 and 50.5 mm) and cross bars(6 - 10mm). The process obtains homogenous weld at every intersection without any scope of air gaps. The Grating thus manufactured dopossess high stability, optimal strength and load distribution and also eliminates any cracks whatsoever.

Types of Grating

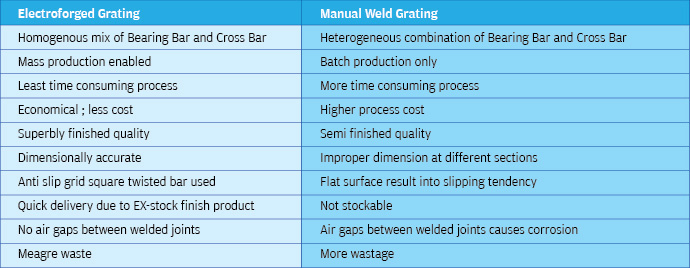

Electroforged Grating vis-a-vis Manual Weld Grating

Ratan's galvanizing Plant with seven tank system, is of international standard to deliver highest quality of corrosion resistance ensuring longevity of gratings.

-

Surface Preparation

Degreasing, rinsing, pickling etc are the basics of Ratan's pre-galvanizing treatment of surface.

Galvanizing

Post fluxing gratings are completely immersed in a bath of minimum 98% pure molten zinc at 4600C.

Finish

Excess zinc is brushed aside and finally quenched and dipped in dichromate solution to ensure long life.

Inspection

Physical and chemical test are conducted subsequently to check adherence, thickness, uniformity of coatings.

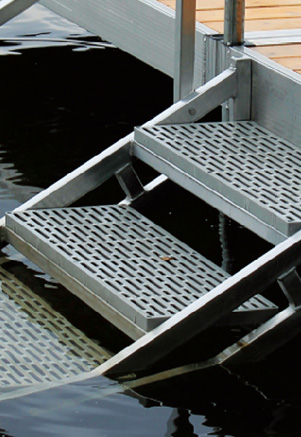

Horizontal Electro Grating Stair Treads are absolutely slip resistant and most ideal at work place. The process of Bar forging always ensures extra grip specially where oil and lubricants are present. Ratan's can manufacture Stair Treads to any spec and length / width.

Why Ratans

Ratan's Electro Gratings Stair Treads with excellent features excel all standards.

- Advantage : Ratan's Electro Gratings Stair Treads eliminate risk of accident in slippery environments

- Availability : It is available in variety and variants of style and spacing to meet up different applications.

- Durability : Electro forged gratings stair tread duly galvanized or paint coated do have high durability and strength which also protects from rust and atmospheric exposure.

Stair treads are utilized by countless industries for a vast array of applications. Stair treads applications to learn more:

- Anti-slip industrial stairway

- Dock stairway

- Non-slip airplane stairway

- School stairway

- Slip resistant commercial stairway

- Slip resistant ship/marine stairway

- Rolling stair platforms and landings

- Water & wastewater stair treads

- Packing platform lines

- Enclosed, semi-enclosed and open stairways

Horizontal Electro Grating Stair Treads are absolutely slip resistant and most ideal at work place. The process of Bar forging always ensures extra grip specially where oil and lubricants are present. Ratan's can manufacture Stair Treads to any spec and length / width.

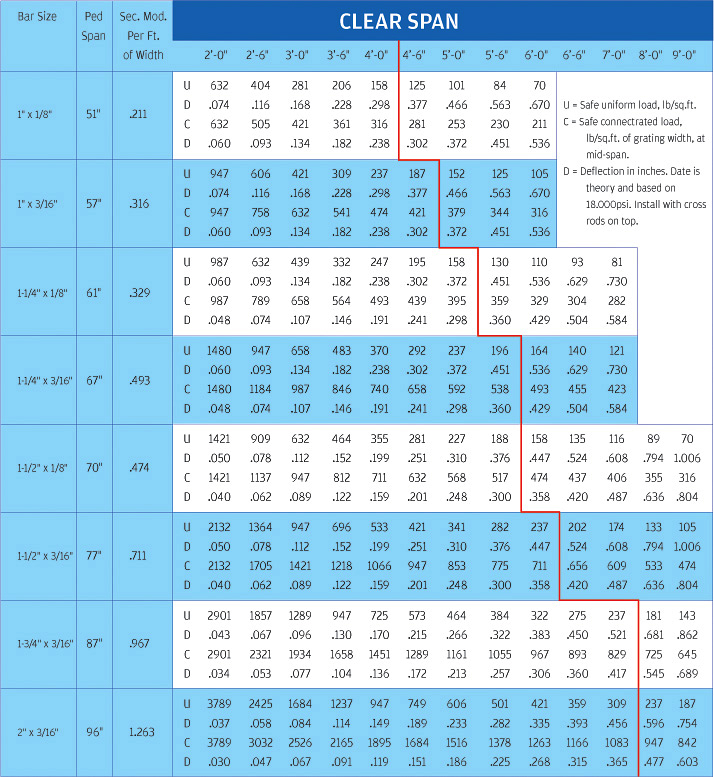

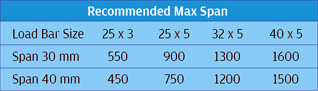

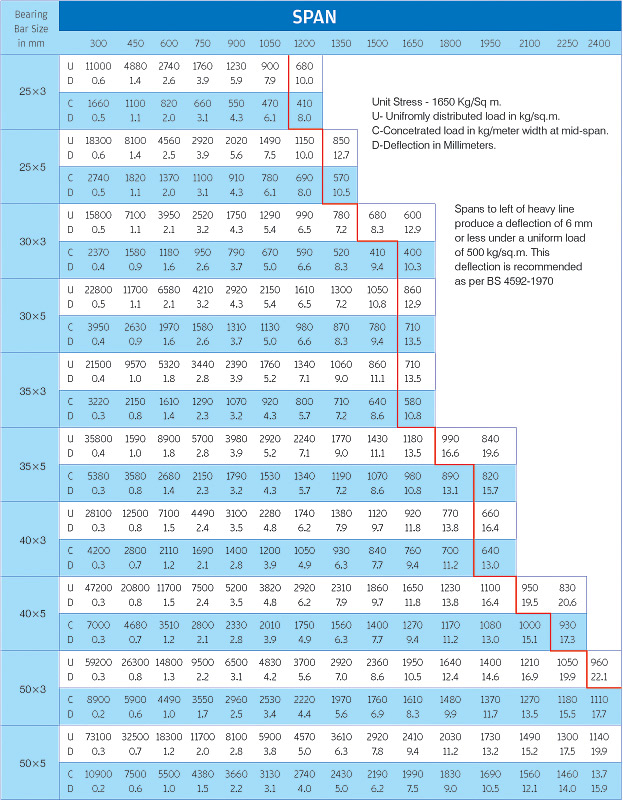

Metric Load table for Electroforge Gratings

41 mm center to center. Types RFB100 & RFB50.

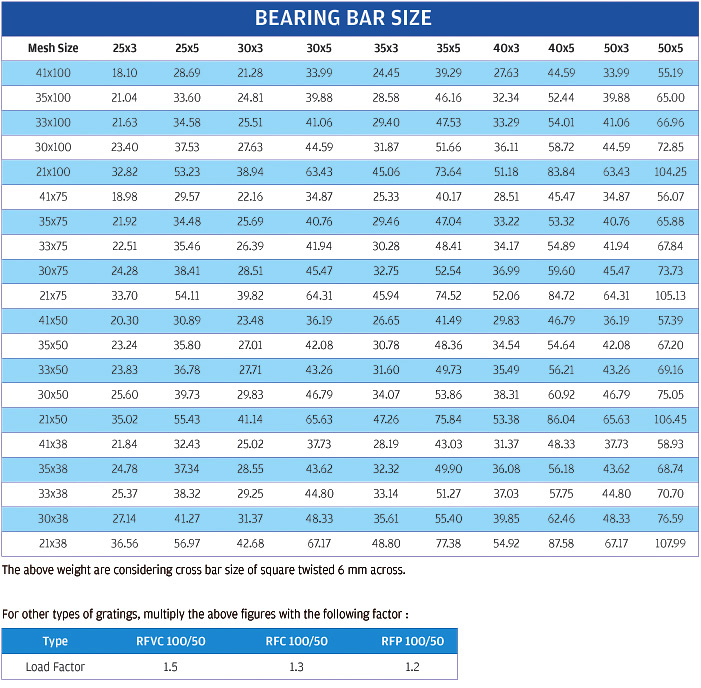

WEIGHT table for Electroforge Gratings

Imperial Load table for Electroforge Gratings

30 mm center to center. Type RFC 100 & RFC 50.